-

Posts

293 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Downloads

Everything posted by kaha

-

I used my normal camera views that I always use. Nothing special.

-

I didn't do anything wired when this happened. I'll try to reproduce.

-

Right, that's the name.

-

John, something strange happened this morning. I was about to test the C-130 Beta by Blackbird and after starting up normally and everything working FSUIPC suddenly got unresponsive for some time. It didn't crash, but after it responded again some inputs didn't work. Looking at the log it turned out that it had terminated my autostarted scripts. Buttons again worked. This happened at 348594 in the log file. Should I account this to the beta version of the Hercules? Karl FSUIPC.zip

-

John, I have a question concerning LuaValue. I have an autoloaded script that handles my throttle and mixture axes. I use "Send to FSUIPC offset" for those axes and in the script I use event. offset. Is this ok or should I better use LuaValue and event.param? Karl

-

Looking good. Logfile attached. Karl FSUIPC7.zip

-

Great, thank you, I'll test it. Karl

-

In the meantime I autostart the script and use "CL16:R". Should still be better than not autostarting the script?

-

The problem with this is that the value doesn't change. It's a trim value, so pressing the button repeatedly it will always send the same value. But event.param is only triggered if the value changes. Karl

-

FSUIPC didn't respond on my last flight. Of course, for testing reasons, I maximize inputs to provoke a possible crashcrash. So this time no inputs were possible anymore but it didn't freeze. I had to use tMenu File->Exit to end it. I restarted it and everything was normal again. Here's the log file. FSUIPC7.zip

-

I didn't use 'AS530_GPS_Outer' Ok, I'll use the new .exe.

-

Here's the log file when FSUIPC AND the sim freezed. Karl FSUIPC7_log.zip

-

That's fine, I will do this. Still log Buttons&Keys in addition? Karl

-

So I tested with 7.5.5a. Exact same behaviour. I probably just didn't notice. Anyway, I'll go on with 7.5.5d and get back to you if it crashes. Karl

-

Yes with 7.5.5d I'll retest with 7.5.5a

-

It was an interesting test. When I was extensively using the trim wheel, throttle and ailerons I experienced the throttle and the ailerons (maybe FSUIPC in total) not responding for as long as up to 2 seconds. But then response was back and it didn't crash. I will go on with this setup and do my normal flights.

-

Ok, got it, I don't make any changes and test repeated trim changes.

-

Yes, as you say it, I was changing trim continuously using my trim wheel. THe trim wheel turns a digital encoder, so button presses come rapidly. If I understand you correctly I for now should not change to autorun the Elevator_Trim script but instead test with no changes running the new .exe file?

-

Ok, I will change it.

-

The crashes don't appear often. I'll use the new .exe from now on. Attached please find the Elevator_Trim script. Elevator_Trim.zip

-

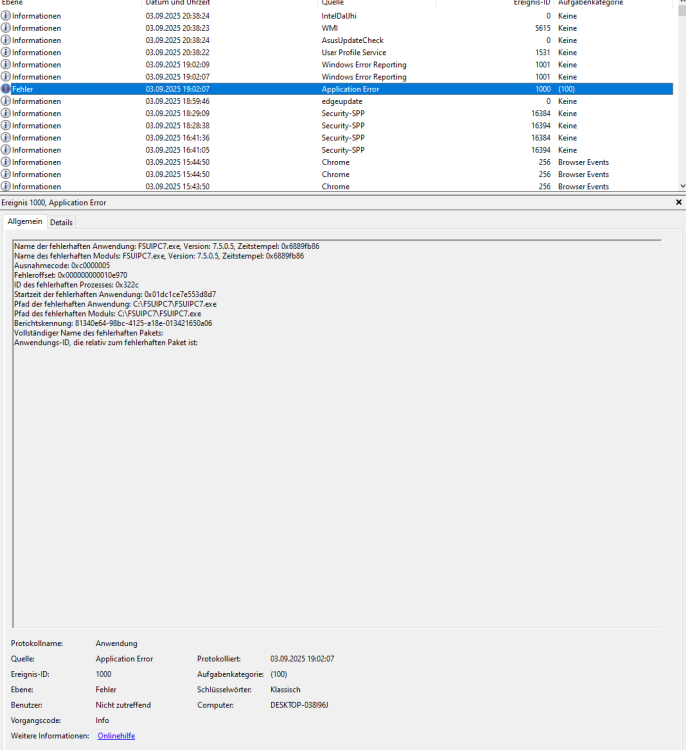

Yes, I ran the same lua scripts in 7.5.4 and there was no crash. Here are the crash details: Protokollname: Application Quelle: Application Error Datum: 03.09.2025 19:02:07 Ereignis-ID: 1000 Aufgabenkategorie:(100) Ebene: Fehler Schlüsselwörter:Klassisch Benutzer: Nicht zutreffend Computer: DESKTOP-038I96J Beschreibung: Name der fehlerhaften Anwendung: FSUIPC7.exe, Version: 7.5.0.5, Zeitstempel: 0x6889fb86 Name des fehlerhaften Moduls: FSUIPC7.exe, Version: 7.5.0.5, Zeitstempel: 0x6889fb86 Ausnahmecode: 0xc0000005 Fehleroffset: 0x000000000010e970 ID des fehlerhaften Prozesses: 0x322c Startzeit der fehlerhaften Anwendung: 0x01dc1ce7e553d8d7 Pfad der fehlerhaften Anwendung: C:\FSUIPC7\FSUIPC7.exe Pfad des fehlerhaften Moduls: C:\FSUIPC7\FSUIPC7.exe Berichtskennung: 81340e64-98bc-4125-a18e-013421650a06 Vollständiger Name des fehlerhaften Pakets: Anwendungs-ID, die relativ zum fehlerhaften Paket ist: Ereignis-XML: <Event xmlns="http://schemas.microsoft.com/win/2004/08/events/event"> <System> <Provider Name="Application Error" /> <EventID Qualifiers="0">1000</EventID> <Version>0</Version> <Level>2</Level> <Task>100</Task> <Opcode>0</Opcode> <Keywords>0x80000000000000</Keywords> <TimeCreated SystemTime="2025-09-03T17:02:07.1416366Z" /> <EventRecordID>159821</EventRecordID> <Correlation /> <Execution ProcessID="0" ThreadID="0" /> <Channel>Application</Channel> <Computer>DESKTOP-038I96J</Computer> <Security /> </System> <EventData> <Data>FSUIPC7.exe</Data> <Data>7.5.0.5</Data> <Data>6889fb86</Data> <Data>FSUIPC7.exe</Data> <Data>7.5.0.5</Data> <Data>6889fb86</Data> <Data>c0000005</Data> <Data>000000000010e970</Data> <Data>322c</Data> <Data>01dc1ce7e553d8d7</Data> <Data>C:\FSUIPC7\FSUIPC7.exe</Data> <Data>C:\FSUIPC7\FSUIPC7.exe</Data> <Data>81340e64-98bc-4125-a18e-013421650a06</Data> <Data> </Data> <Data> </Data> </EventData> </Event> Karl

-

Forgot the .zip file. Kaha.zip

-

The crashes are only with version 7.5.5a Here's the Windows log. Is this what you want to see? I do not terminate autostarted scripts intentionally nor do I know of any code in my scripts that would terminate them. Maybe this is a message that shows FSUIPC is waiting for my event.terminate function? As an example please find my L_Centurion21.lua script in the .zip file. (This is a script handling a Centurion Autopilot hardware device). All my scripts use the event.terminate function. Some wouldn't need it (they just do a log line), but others do need it, like for closing open COM ports. I also include a normal .log file, it also has the same messages about waiting for lua threads to process termination event..... From all 13 autostarted scripts only one is aircraft specific (L_B18_TankSwitch) and yes, you are right, I should and I will put it into the profile specific Auto section. But, I have a thought: Could it be that this error message 5158344 *** LUA Error: C:\FSUIPC7\lua\l_kaha_lua.lua:967: Error sending Input Event 'AS530_GPS_Outer' causes the crash after some time? Karl

-

At the end of the flight, just short of touchdown in the Albatross. Didn't happen the first time, it crashed a few times also in different aircraft. But this time I'll report it. Please find the log and the ini file attached. Karl Crash_kaha.zip